USA &CA ETL Listed Led Neon Strip

New Arrival COB brightest neon rope light 800Lumens/M, max run 164ft.

110V LED Neon Rope Light

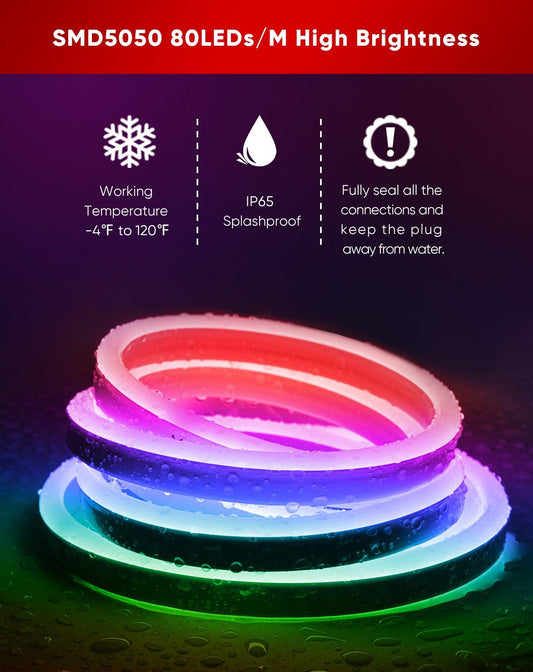

ETL Listed IP65 LED neon light, best for indoor/outdoor creating lighting atmosphere. Match accessories to offer, easy connect, flexible, and dimmable.

Don't want to see bulbs within the led light, please choose the LED neon rope light collection.

110V LED Strip Light

ETL-listed IP65 LED strip, best outdoor/indoor lighting hidden from direct view instead of pendant offers lighting. Match accessories to offer, easy connect, flexible, and dimmable.

Want to see bulbs within LED light, you can choose the LED strip light collection.

Smart silicone neon rope light

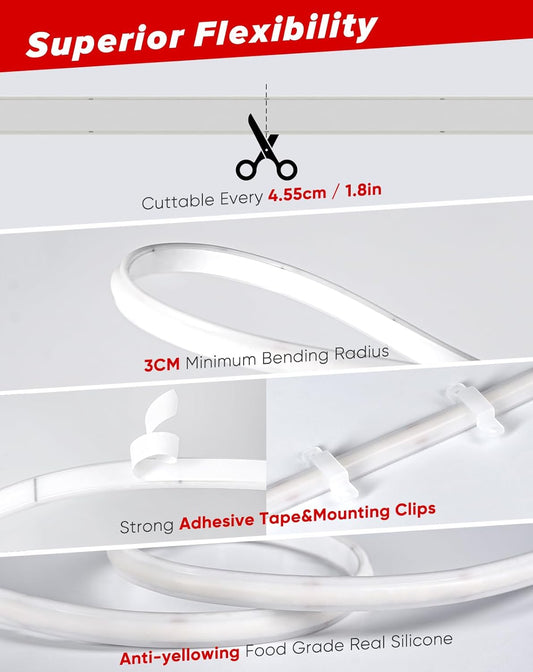

Easy cut into small neon unit, used for neon styling design.

Best selling

-

110V Eco LED Neon Rope Light 6000K Cool White Energy Efficient 189Lumens/M

5.0 / 5.0

(4) 4 total reviews

Regular price From $35.99Regular priceUnit price / per -

110V Eco RGB LED Neon Rope Light Long Lasting Bright Remote Control

3.75 / 5.0

(4) 4 total reviews

Regular price From $59.99Regular priceUnit price / per -

110V Led Neon Rope Light 6500K Cool White Proselect Neon High-Priced 220Lumens/M

5.0 / 5.0

(2) 2 total reviews

Regular price From $48.99Regular priceUnit price / per -

110V Super Bright Lum LED Neon Rope Light 6300K Cool White 226Lumens/M

Regular price From $38.99Regular priceUnit price / per

New arrival

-

110V Ultra Bright COB LED Neon Rope Light 6000K Cool White 800Lumens/M

Regular price From $49.99Regular priceUnit price / per -

110V Ultra Bright COB LED Neon Rope Light 2800K Warm White 800Lumens/M

Regular price From $49.99Regular priceUnit price / per -

24V IP67 Smart RGB Strip Super Waterproof Pool Strip Lighting

Regular price From $49.99Regular priceUnit price / per -

110V Lower Brightness RGB LED Strip Light-Lite RGB Strip Soft Ambient Lighting

Regular price From $32.99Regular priceUnit price / per

Let customers speak for us

from 34 reviewsUsed this for our business sign as a back light and it looks great. I should have paid more attention to the listing because this particular model does not come with a remote so it has to be hooked up to a plug on a switch or be unplugged when not in use but that is no fault of the product only my own.

These lights replaced some tube lights that were starting to fail. They are true daylight. Colour and brightness is great.

110V High-Priced LED Neon Light-ProSelect Neon 6500K Cool White

50' Cool White rope. The plug was cut off and the rope is spliced to 110V supply in an electrical box

Made the building light up. Looks great.

Neon rope light @ 16,4 was used on a cantilever section of the back deck to highlight the river rock below. Have had great success with shine decor in some of my other lighting project. Excellent product. Length chosen to accommodate deck width to minimize waste.

The light puts out nice consistent light, better then i expected even. The track was a little awkward to work with cause of the tiny screws provided but once in place it looks real nice. The longer track is definitely recommended if straight lines are the goal. Will certainly come back for more should i have a place that could use the added ambience or added light.

I was installing lights on the ledge of my back porch and the channel track worked perfectly for a clean install.

110V 7x13.5mm LED Strip Light-ColdProtect Strip

RGB Silicone Neon Light with APP Bluetooth

great service

Hieverything seems to be ok, but because of COVID 19, I havent been able to have it installed, it will be installed in 2 months from now. I will get back to you then.

Thank you

The material is well made and rugged enough to ensure confidence in using it outdoors. I have looked at several neon rope lights and this system is on par with rope lights which are far more expensive. Shine does need to look at developing connectors which accommodate 90-degree corners which are an issue in any installation. If they can fulfill this requirement, I believe their rope light system sales will really take off. Hint: look carefully at your straight 2-pin straight connector and simply have the rigid plastic connector formed as an 90-degree 2- pin fixture.